UBACK Technical Guidelines

- How does the UBackTool works?

- UBack Programming guidelines - Continuous Cut

- UBack Programming guidelines – Interrupted Cut

- Counterbore Machining Guidelines for Specific Conditions

- UBack Insert Replacement

- Configuring UBACK tool-holders for different cooling systems

- UBack cutting recommendations

- Coatings Types

- Chip-formers

- NEW UBACK-USPOT Insert and Tool-Holder Configurator

- NEW UBACK-UCHAMF Insert and Tool-Holder Configurator

How does the UBackTool works?

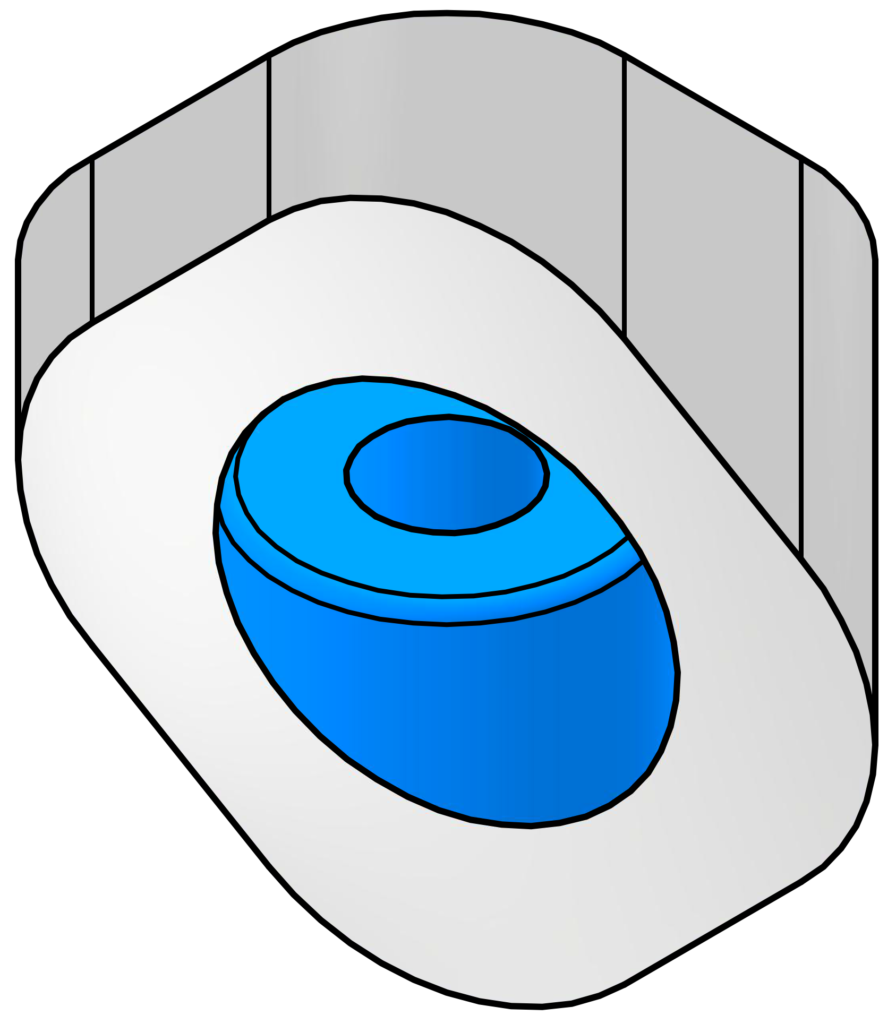

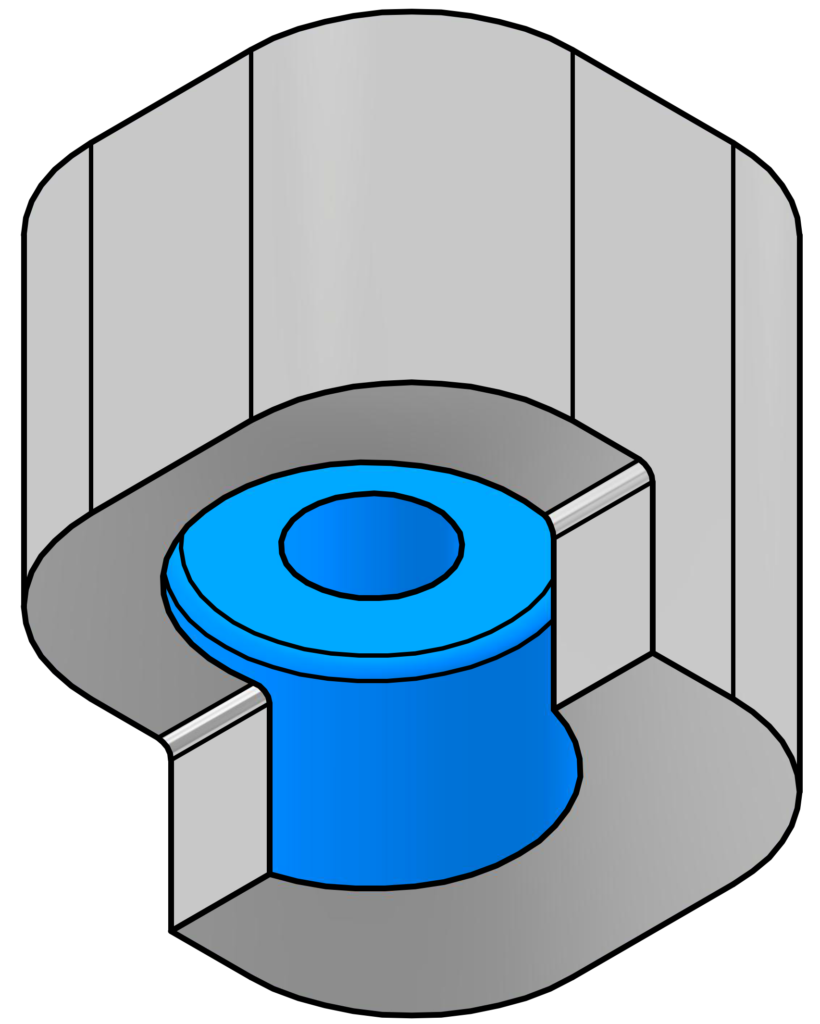

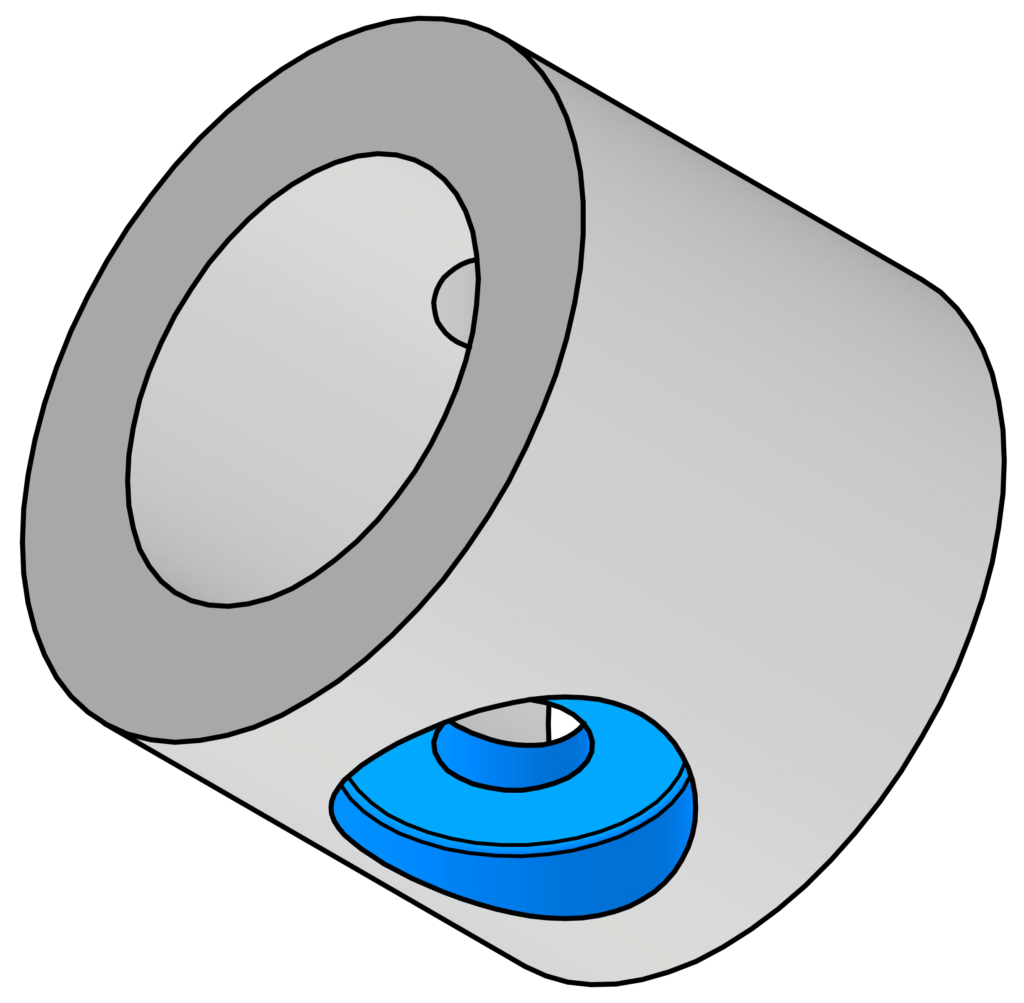

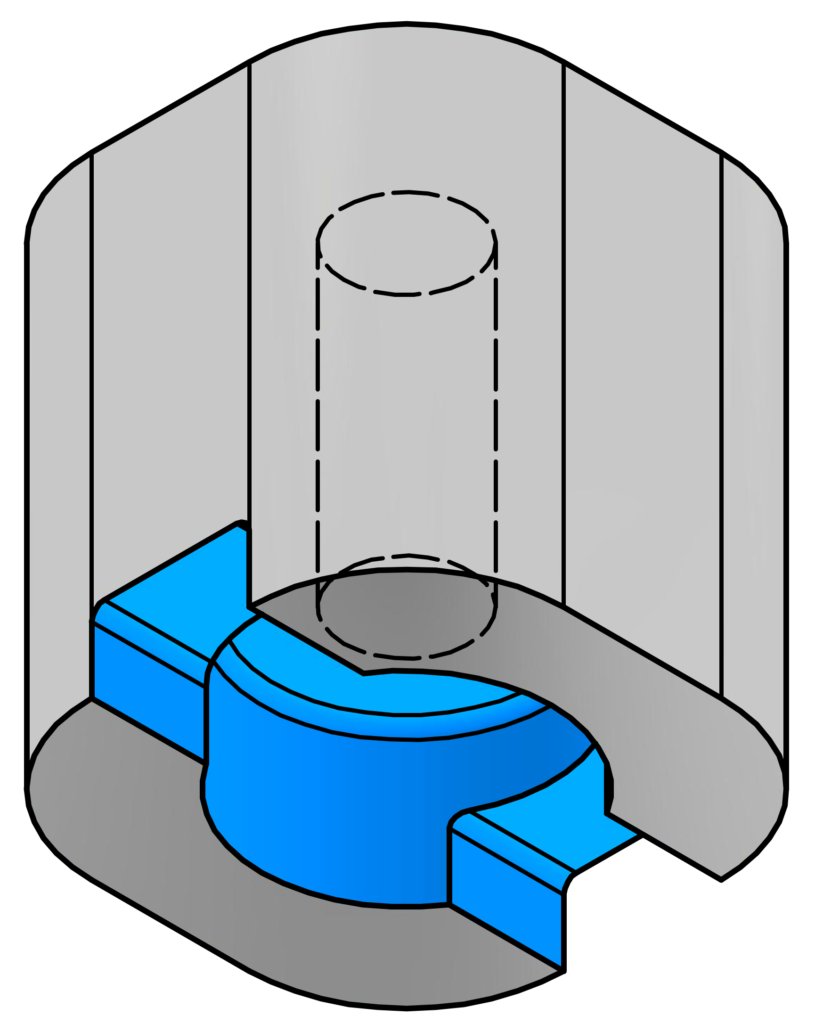

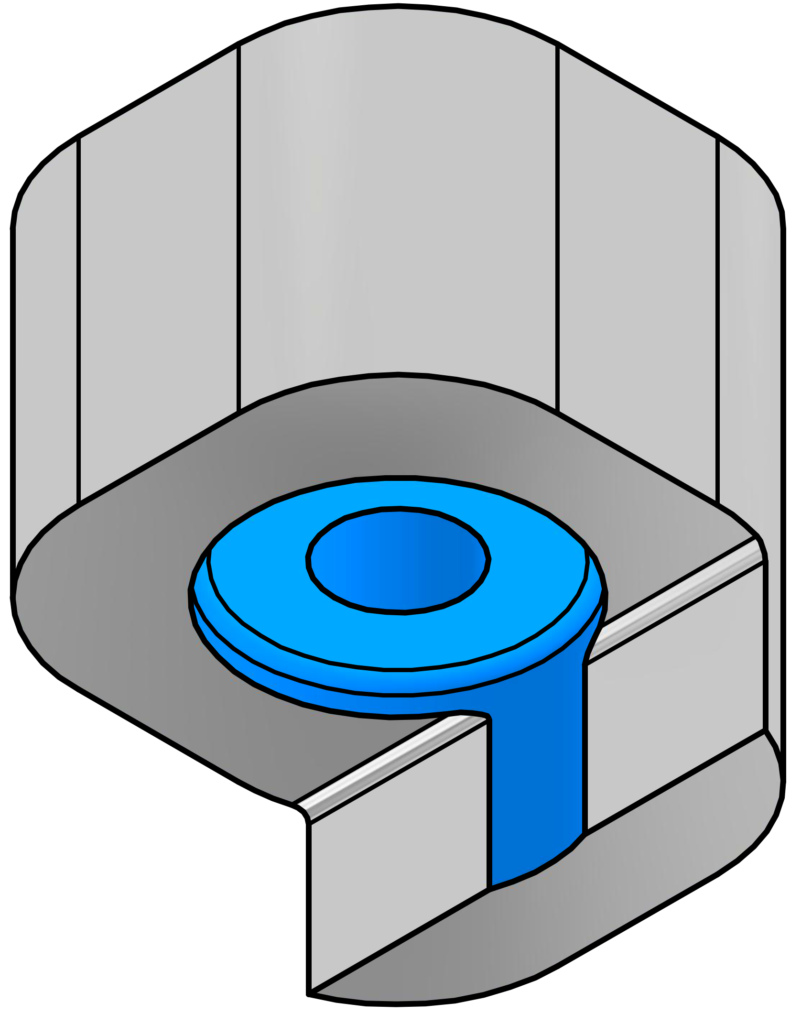

- The UBack tool-holders are designed for CNC automated operations and are compatible with USPOT inserts for back counterboring and spot-facing, as well as UCHAMF inserts for back countersinking.

- The insert’s opening and closing hydraulic mechanism is activated by directing coolant through the spindle and tool-holder. This system supports coolant, emulsion, or air with a minimum pump pressure of 6 bar (90 PSI).

- The tool-holder is specifically engineered to prevent scratches while passing through the pilot hole.

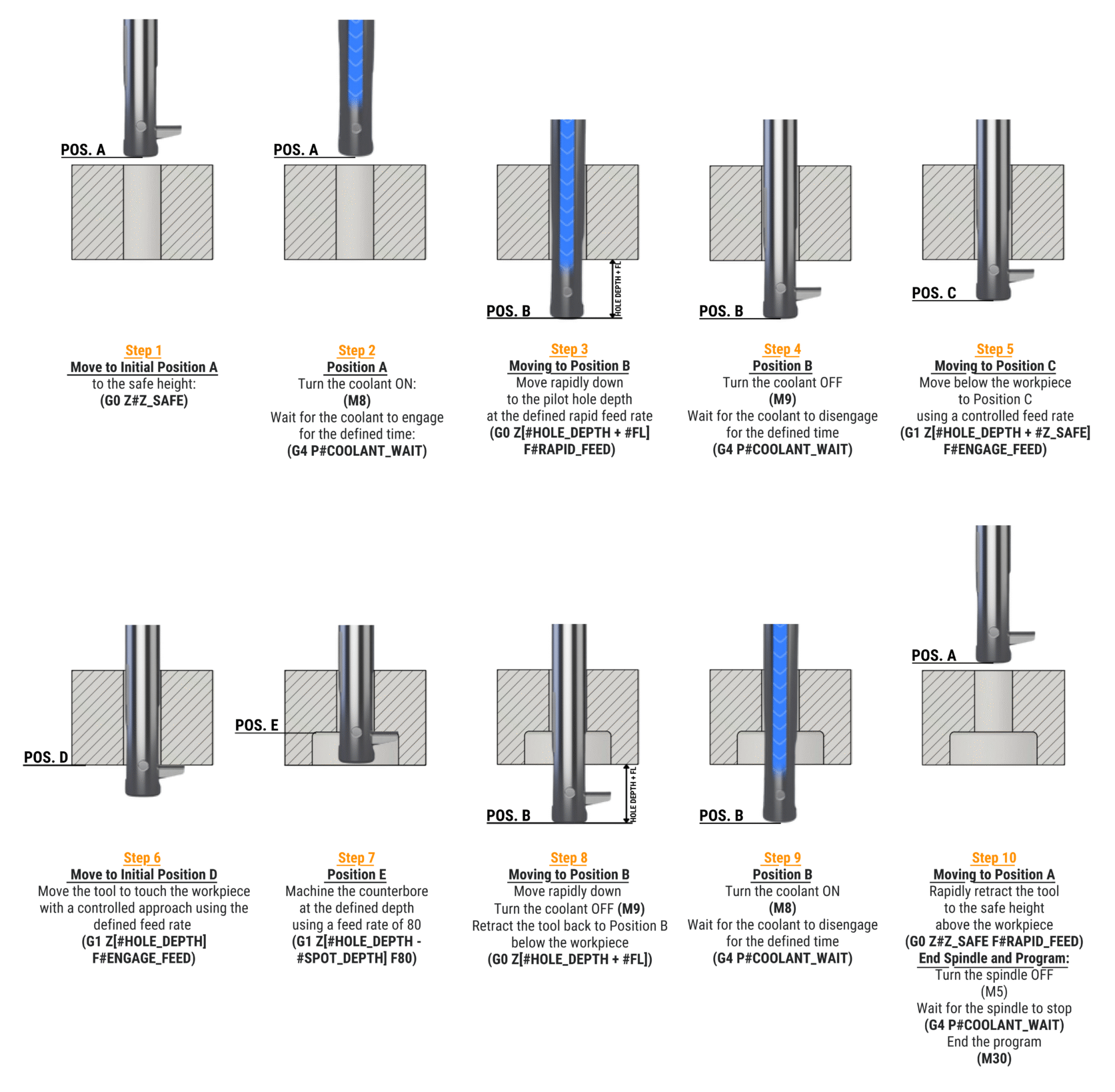

(1) The Folding Length (FL) parameter is listed in the tool-holder tables and is the same for both USPOT inserts and UCHAMF inserts.

(2) The illustrated operation sequence above demonstrates working with a USPOT insert but remains the same when using a UCHAMF insert.

UBack Programming guidelines – Interrupted Cut

For interrupted cuts:

Step 6–7 → Perform without internal coolant

Use external coolant only (also refer below “Counterbore Machining Guidelines for Specific Conditions”)

(1) The Folding Length (FL) parameter is listed in the tool-holder tables and is the same for both USPOT inserts and UCHAMF inserts.

(2) The illustrated operation sequence above demonstrates working with a USPOT insert but remains the same when using a UCHAMF insert.

Counterbore Machining Guidelines for Specific Conditions

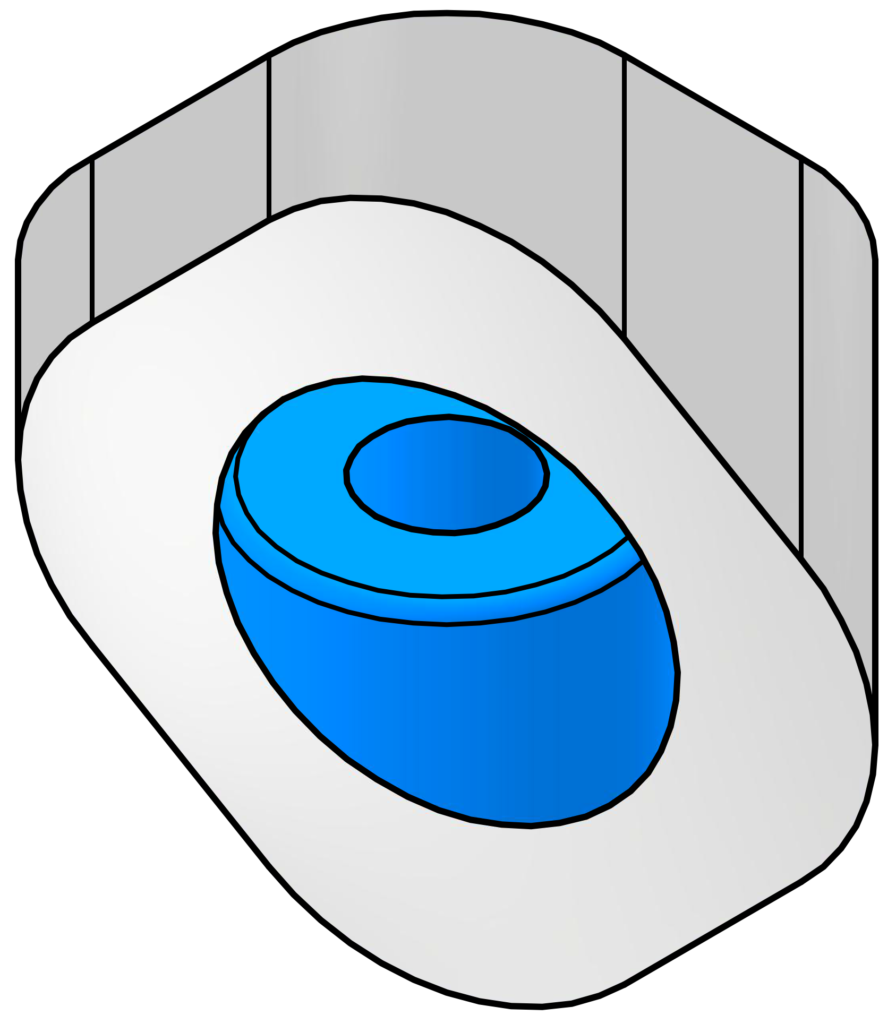

Counterbore on Cylindrical Bore

- Use with Internal Coolant

Counterbore on Sloped Surface

- Use external coolant only

- Fully Interrupted Cut

- Use external coolant only

- Consider reduced stability and adjust cutting parameters by reducing them by 30%

- Fully Interrupted Cut

- Use external coolant only

- Consider reduced stability and adjust cutting parameters by reducing them by 30%

- Fully Interrupted Cut

- Use external coolant only

- Consider reduced stability and adjust cutting parameters by reducing them by 30%

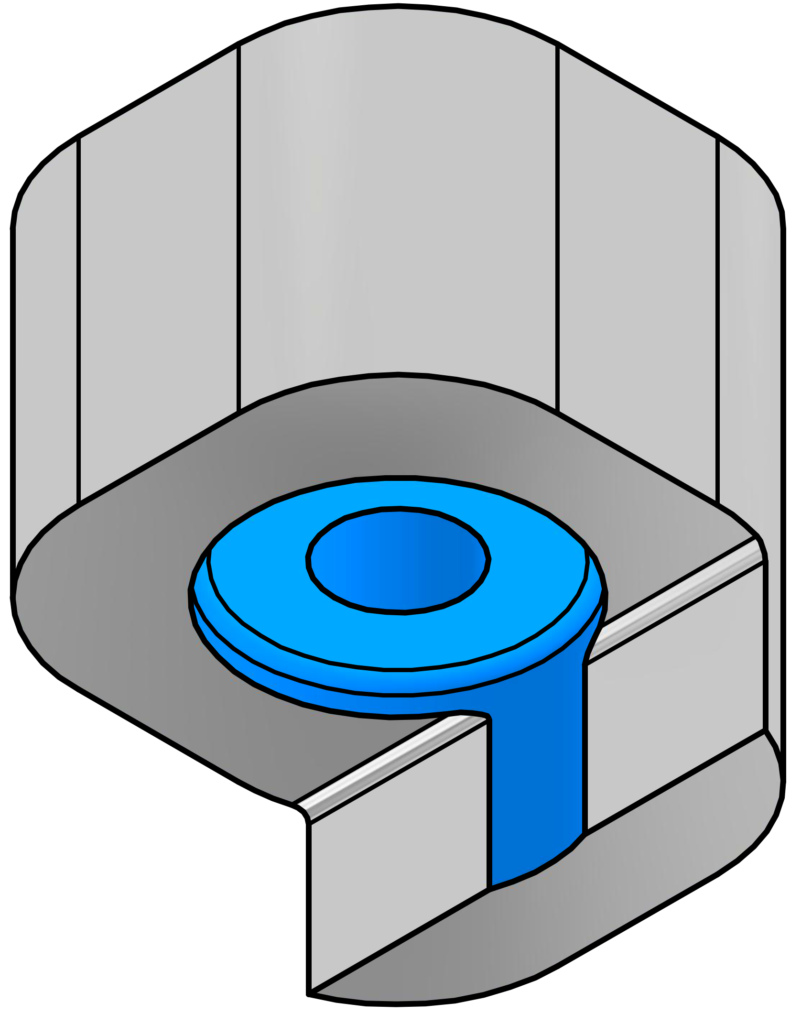

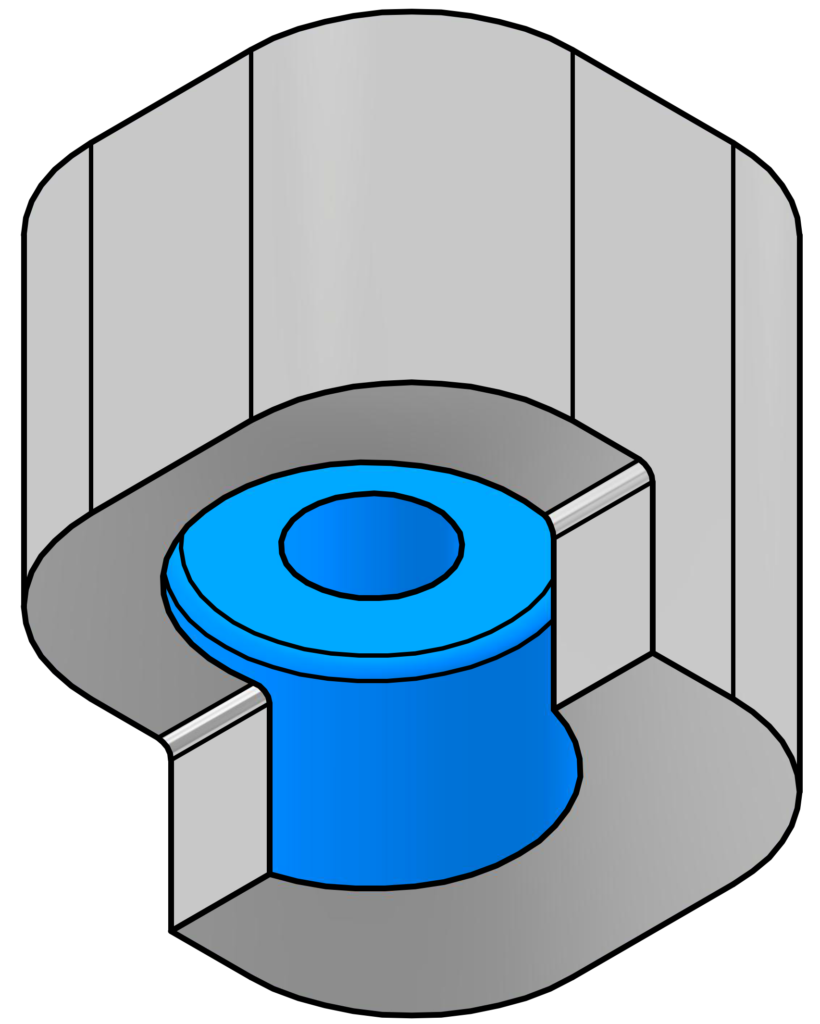

UBack Tool Insert Replacement

- UBack inserts can be easily replaced using just a pin and a screw, without the need for any additional mounting devices.

- The pin is used to secure the insert within the tool-holder, preventing it from retracting while unscrewing.

- The UBack spare parts, including the screw, key, and pin, are standardized across the entire UBack tool-holder range.

NOTE: The illustrated insert replacement above is demonstrated with a USPOT insert but remains the same when using a UCHAMF insert.

Configuring UBACK tool-holders for different cooling systems

UBack Cutting Recommendations

The table below presents cutting recommendations, outlining initial feed rates and cutting speed for materials group based on ISO 513 and VDI 3323 standards.

(1) To ensure optimal performance and tool-life under varying conditions:

- For moderate tool-holder or workpiece stability, consider reducing feed rates by up to 10%.

- For poor tool-holder or workpiece stability, it’s advisable to decrease feed rates by up to 30%.

Additionally, the operator must ensure the utilization of appropriate coolant media directed to the cutting tip of the blade and right-hand machining (clockwise).

|

ISO |

Material |

Condition |

As is |

DIN W.-Nr. |

vc(1) cutting speed |

Series B |

Series C |

Series D |

Series E |

Series F |

Series G |

Recommended |

Coolant |

|

|||

|

P |

Non-alloy steel |

<0.25% C |

Annealed |

1020 |

1.0044 |

60-120 |

0.03 |

0.04 |

0.05 |

0.07 |

0.08 |

0.09 |

PL ML |

Air / Wet |

|||

|

≥0.25% C |

Annealed |

1035 |

1.0501 |

||||||||||||||

|

<0.55% C |

Quenched and tempered |

1045 |

1.1201 |

||||||||||||||

|

≥0.55% C |

Annealed |

1055 |

1.0535 |

||||||||||||||

|

Quenched and tempered |

1060 |

1.1221 |

|||||||||||||||

|

Low alloy |

Annealed |

G92600 |

1.5028 |

50-120 |

0.03 |

0.04 |

0.05 |

0.07 |

0.08 |

0.09 |

|||||||

|

Quenched and tempered |

4130 |

1.7218 |

|||||||||||||||

|

4142 |

1.2332 |

||||||||||||||||

|

5045 |

1.7006 |

50-100 |

|||||||||||||||

|

High alloyed steel, |

Annealed |

H13 |

1.2344 |

40-90 |

0.02 |

0.03 |

0.04 |

0.05 |

0.06 |

0.08 |

|||||||

|

Quenched and tempered |

M33 |

1.3249 |

|||||||||||||||

|

Stainless steel and cast

steel |

Ferritic/martensitic |

420 |

1.4021 |

||||||||||||||

|

Martensitic |

|||||||||||||||||

|

M |

Stainless steel |

Austenitic, duplex |

304L |

1.4306 |

50-100 |

0.03 |

0.04 |

0.05 |

0.07 |

0.08 |

0.09 |

PL |

Wet |

||||

|

K |

Gray cast iron (GG) |

Ferritic / pearlitic |

Class 25 |

0.6015 |

60-120 |

0.03 |

0.04 |

0.05 |

0.07 |

0.08 |

0.09 |

PL |

Air / Wet |

||||

|

Pearlitic / martensitic |

Grade H20 |

36037 |

|||||||||||||||

|

Nodular cast iron (GGG) |

Ferritic |

60-40-18 |

0.7043 |

50-100 |

0.02 |

0.03 |

0.04 |

0.05 |

0.06 |

0.08 |

|||||||

|

Pearlitic |

F33500 |

0.705 |

|||||||||||||||

|

Malleable cast iron |

Ferritic |

A47 |

0.8135 |

||||||||||||||

|

Pearlitic |

A220 Class |

0.8155 |

|||||||||||||||

|

N |

Aluminum-wrought alloys |

Not hardenable |

5005 |

3.3315 |

100-160 |

0.05 |

0.06 |

0.08 |

0.10 |

0.12 |

0.14 |

PL |

Wet |

||||

|

Hardenable |

7075 |

3.4365 |

|||||||||||||||

|

Aluminum-cast alloys |

≤12% Si |

Not hardenable |

518 |

3.3292 |

|||||||||||||

|

Hardenable |

515 |

3.3241 |

|||||||||||||||

|

>12% Si |

High temperature |

390 |

|

||||||||||||||

|

Copper alloys |

>1% Pb |

Free cutting |

C36000 |

2.0375 |

90-130 |

||||||||||||

|

|

Brass |

C22000 |

2.023 |

||||||||||||||

|

Electrolytic copper |

C63000 |

2.0966 |

|||||||||||||||

|

Non metallic |

Duroplastics, fiber

plastics |

Bakelite |

|

180-305 |

|||||||||||||

|

Hard rubber |

Ebonite |

|

|||||||||||||||

|

S |

High temperature alloys |

Fe based |

Annealed |

330 |

1.4864 |

40-80 |

0.02 |

0.03 |

0.04 |

0.05 |

0.06 |

0.08 |

PL ML |

Wet |

|||

|

Hardened |

S590 |

1.4977 |

|||||||||||||||

|

Ni or Co based |

Annealed |

Incoloy 825 |

2.4858 |

25-40 |

|||||||||||||

|

Hardened |

Inconel 718 |

2.4668 |

|||||||||||||||

|

Cast |

Nimocast K24 |

2.4674 |

|||||||||||||||

|

Titanium alloys |

Pure |

Titanium G.1 |

3.7024 |

30-60 |

0.02 |

0.03 |

0.04 |

0.05 |

0.06 |

0.08 |

|||||||

|

Alpha+beta alloys,

hardened |

Titanium G.5 |

3.7165 |

|||||||||||||||

|

H |

Hardened steel |

Hardened |

HARDOX 500 |

|

30-50 |

0.02 |

0.02 |

0.03 |

0.04 |

0.05 |

0.06 |

ML HL |

Air |

||||

|

Hardened |

HARDOX Extreme |

|

30-40 |

||||||||||||||

|

Chilled cast iron |

Cast |

A532 lllA 25% Cr |

0.965 |

45-50 |

0.02 |

0.02 |

0.03 |

0.04 |

0.05 |

0.06 |

|||||||

|

Cast iron |

Hardened |

A532 IID 20% CrMo |

0.9645 |

30-50 |

0.02 |

0.02 |

0.03 |

0.04 |

0.05 |

0.06 |

|||||||

(1) To ensure optimal performance and tool-life under varying conditions:

- For moderate tool-holder or workpiece stability, consider reducing feed rates by up to 10%.

- For poor tool-holder or workpiece stability, it’s advisable to decrease feed rates by up to 30%.

Available Coating types and surface treatments:

|

NOGA’s Code |

Coating |

Key Features |

Applications |

Industries |

Material Examples |

ISO GROUP |

|||||

|

P |

M |

K |

N |

S |

H |

||||||

|

NCT |

TiAlN |

Excellent thermal

stability, oxidation resistance, and wear resistance. |

High-speed cutting and

general-purpose machining. Works in wet & dry conditions. |

Aerospace, Automotive, General Engineering |

AISI 304, 42CrMo4,

Grey Cast Iron (GG), Ti6Al4V |

✓ |

✓ |

✓ |

X |

✓ |

✓ |

|

NCD |

TiAlSiN |

Very high hardness,

extreme oxidation resistance (>1200°C). Excels in dry machining at high

speeds. Suitable for hardened

steels >45 Rc. |

High-performance

machining in demanding environments. |

Aerospace, Automotive, Die & Mold |

Inconel 718, AISI

4140, Ti6Al4V, Hastelloy |

✓ |

✓ |

X |

X |

✓ |

✓ |

|

NCA |

AlTiSiN |

High hardness, thermal

stability, and wear resistance. Works well in dry,

high-speed cutting. Suitable for hardened

steels >45 Rc. |

High-speed machining

in extreme conditions. |

Aerospace, Automotive, Precision Engineering |

AISI 316, AISI H13,

Hastelloy |

✓ |

✓ |

X |

X |

✓ |

✓ |

|

NCN |

AlCrN |

High oxidation

resistance (to 1100°C), toughness, abrasion resistance. |

General machining in

abrasive/wet conditions. |

Automotive, Aerospace, Die & Mold |

AISI 304, AISI 1045,

Grey Cast Iron (GG), AL6061, Die Steels |

✓ |

✓ |

✓ |

✓ |

X |

X |

|

NCW |

AlTiN |

High hardness, wear

resistance, thermal stability up to 1100°C. |

Heavy-duty machining

and high-speed cutting. Dry & abrasive

conditions. |

Aerospace, Automotive, Heavy Engineering |

AISI 4340, M2 HSS,

Grey Cast Iron (GG) |

✓ |

✓ |

✓ |

X |

✓ |

X |

|

NCB |

TiB₂ |

Excellent thermal

stability, hardness, and very high conductivity. Prevents material

adhesion and BUE. |

High-speed machining

of non-ferrous metals. |

Aerospace, Automotive,

Electronics |

AL7075, 6061-T6,

Copper, Magnesium Alloys (AZ31), SiC composites |

X |

X |

X |

✓ |

✓ |

X |

|

POL |

Polishing (Surface

Treatment) |

Removes scratches,

burrs, and micro-defects. Produces smooth finish and reduces friction. |

High-speed finishing

of non-ferrous materials. Improves MRR and surface aesthetics. |

Aerospace, Automotive |

AL7075, 6061-T6,

Copper, Magnesium Alloys (AZ31) |

X |

X |

X |

✓ |

X |

X |

Chip-formers:

PL

Positive cutting land

Suitable for all around purpose

and ISO P,M,K,N,S

as well as composite materials

ML

Moderate cutting land

Suitable for and ISO P,M,K,S,H

Materials

HL

Negative cutting land

Suitable for and ISO P,M,K,S,H

Materials

👨🔧 USPOT Configurator

Insert & Tool-Holder Code Generator

👨🔧 UCHAMF Configurator

Insert & Tool-Holder Code Generator