Case Study #6 UBURR

Industry: Medical

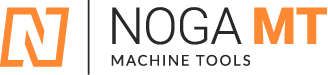

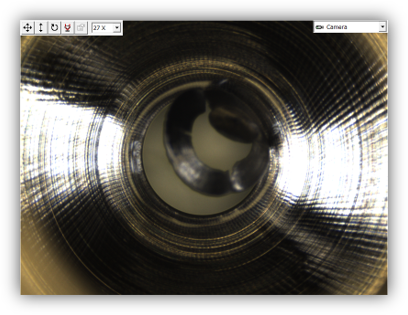

Objective: Deburr the rear section of machined drills for a medical component.

Application details:

- Material: 17-4 PH, Wr N.1.4542

- Pilot Hole: Ø2.73 /.1075”

- Pilot Holes Length: H1=12mm / .472”

- Machine: Star SR-20 JII TYPE B

- Production Volume: 3000 parts/month

Tool-holder:

- UB2500; UBS-d025-C08-H29-L65

Blade:

- UB2022; UB-TSB-2.5-PL-NCT

Machining Parameters:

|

Ød Pilot Hole |

S Spindle Speed |

F Table Feed |

vc Cutting Speed |

fz Feed per tooth |

Coolant |

||||

|

mm |

Inch |

RPM |

mm/min |

inch/min. |

m/min. |

sfm |

mm |

inch |

|

|

2.72 |

0.1075 |

4500 |

100 |

2 |

40 |

1.575 |

0.025 |

0.009 |

Oil |

Results: The burrs were effectively eliminated, leaving 0.17×45° chamfers.

Key Points:

Manual vs. Automatic

– Manual operation: 1 minute

– UBURR automatic operation: 5 seconds

– ~92% cycle time reduction

Customer Savings (per month)

– 46 hours saved = $1,500 labor cost reduction

– $1,750 tooling cost reduction

– Total monthly savings: $3,250

UBURR Investment (per month)

– Tool cost: $79

ROI Impact

– ROI = ~40,000% per month

– Investment pays back 400× within the first month

Spend $79 – Save $3,250 every month with UBURR.