Point Brush Machining Guidelines and safety Instructions:

Features:

- Suitable for precision work in small or complex areas, ideal for removing cutter marks, polishing, and finishing parts with small or narrow features.

- Suitable for use in CNC machines, robots, or hand-held rotary tools.

Machining Recommendations:

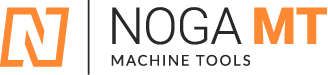

Dimensions for 1.0-2.0mm (0.039-0.079") Point-brush

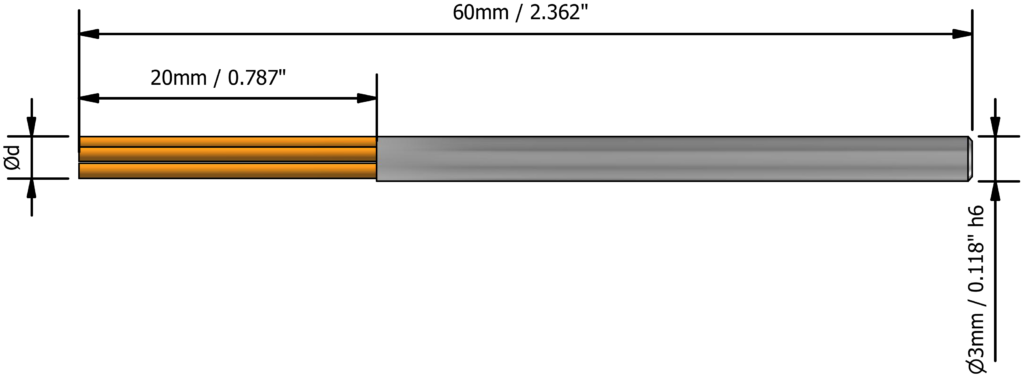

Dimensions only for 2.5 and 3mm (0.098,0.118") Point-brush

|

Description |

Ød |

Spindle |

|

|

min. |

max. |

||

|

mm |

min-1 |

||

|

UF-PB-…-D1-L20 |

1.0 |

– |

12000 |

|

UF-PB-…-D1.5-L20 |

1.5 |

– |

12000 |

|

UF-PB-…-D2-L20 |

2.0 |

– |

12000 |

|

UF-PB-…-D2.5-L20 |

2.5 |

– |

12000 |

|

UF-PB-…-D3-L20 |

3.0 |

– |

12000 |

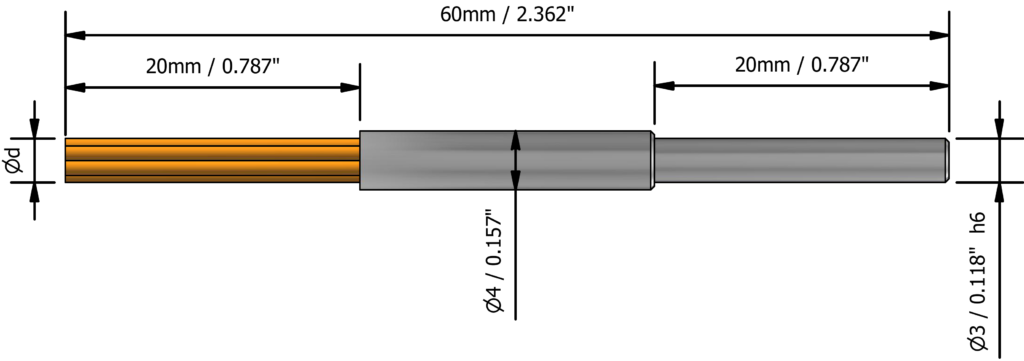

Grit Selection by Burr Condition & Material

Point Brush Installation and Usage:

- Shank Grip: Ensure that the shank is gripped by at least 20 mm to avoid detachment due to vibrations, which could lead to serious injury.

- Chuck Matching: Use a chuck that matches the diameter of the shank.

- Tool Compatibility: The brush is designed for use with hand-held rotary tools and CNC machines. It can handle precise finishing tasks in tight or recessed areas where traditional brushes may not perform as well.

Important Guidelines for Manual Use of the Point-Brush

- When operating the point-brush manually with a micromotor tool or any motorized hand-held device, ensure a firm grip on the tool before starting. Set the initial speed to 1,000 RPM and gently bring the brush into contact with the workpiece. As you gain better control and stability, and depending on the grit size of the point-brush, you may gradually increase the speed up to 3,000 RPM. However, exceeding this speed is not recommended, as it may cause the tool to pull away or become difficult to control.

- When using the point-brush on CNC machines or in applications where both the workpiece and the brush are securely clamped, the rotational speed can be increased according to the recommendations in the table above.

Point Brush Safety Precautions:

- The brush is not recommended for use with pneumatic-powered tools due to safety concerns.

- Operators must wear appropriate personal protective equipment (PPE), including goggles, masks, gloves, and hearing protection.

- Speed limits should be strictly followed to avoid overheating, detachment, or bristle breakage.

Point Brush Safety Instructions:

- Using the product in ways not specified in the guidelines may result in serious injuries or fatalities.

- Eye and skin protection is essential as particles, debris, or burrs generated during processing can cause severe injuries.

- Stop using the brush if you detect any vibration or unusual occurrences. Continuing under such conditions increases the risk of tool detachment or workpiece damage.

- Overheating risk: Prolonged machining at a constant point can cause overheating, increasing the risk of bristle detachment or breakage. Operators should avoid direct contact with the machined area after use to prevent burns.

Fire and Work Area Safety:

- The tool may generate heat or sparks, so avoid using it near flammable liquids or explosive atmospheres.

- Ensure the work area is clean, and barriers are in place to prevent unauthorized personnel from entering. Everyone in the area should wear protective gear.

Handling of Cutting Particles:

- Use a dust collection system to capture the fragments and debris generated during processing.