Case Study #1 UBURR

Industry: Automotive

Objective: Conduct comparison tests against competitors

for removing burrs from the front and rear of machined drills.

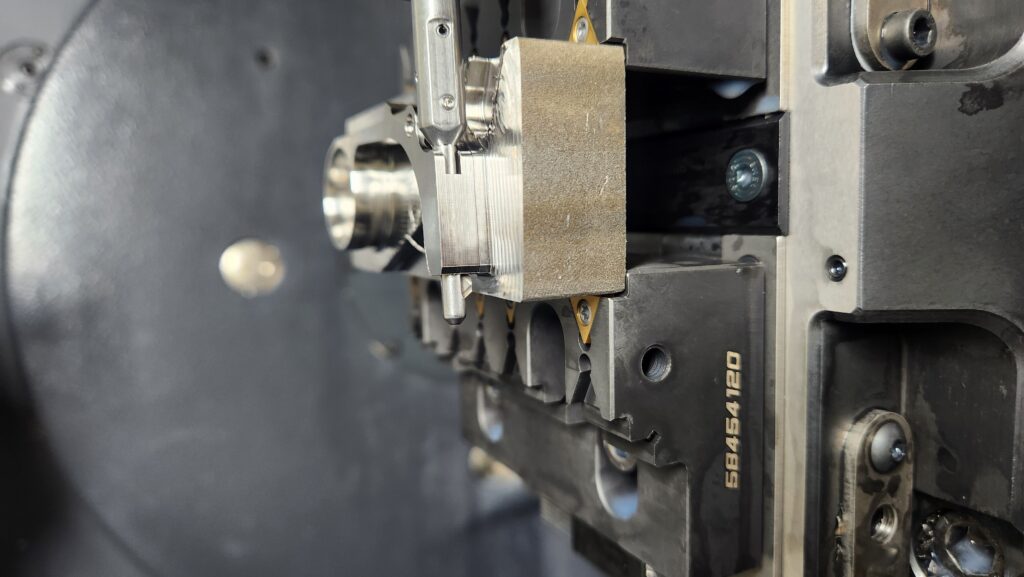

Application details:

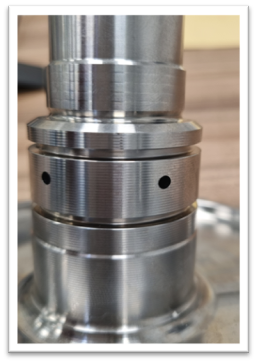

- Part: Transmission Shaft

- Material: AISI 4340, Wr N.1.6928

- Pilot Holes: Ø2.5 and Ø3.0mm / .098 and .315”

- Pilot Holes Length: H1=35mm / 1.38”

- Production Volume: 45000 bores/month

Tool-holder Sets:

- UB2500; UBS-d025-C08-H29-L65

- UB3000; UBS-d030-C08-H29-L85

Blades:

- UB2022; UB-TSB-2.5-PL-NCT

- UB2032; UBS-TSB-3.0-PL-NCT

Machining Parameters:

|

Ød Pilot-Hole |

S Spindle

Speed |

F Table

Feed |

vc Cutting

Speed |

fz Feed

per tooth |

Coolant |

||||

|

mm |

Inch |

RPM |

mm/min |

inch/min. |

m/min. |

sfm |

mm |

inch |

|

|

2.5 |

0.098 |

2000 |

500 |

20 |

16 |

52 |

0.25 |

0.01 |

External

Emulsion |

|

3.0 |

0.118 |

2000 |

500 |

20 |

19 |

62 |

0.25 |

0.01 |

External

Emulsion |

Results:

The customer expressed great satisfaction with the outcomes, particularly noting the enhanced tool longevity and surface finish, which were verified using an endoscope.

|

|

Ød Pilot Holde |

|

|

2.5mm / 0.098” |

3.0mm / 0.118” |

|

|

Numbers of Holes |

||

|

NOGA |

210 |

1300 |

|

Competitor |

100 |

500 |