UFIBER

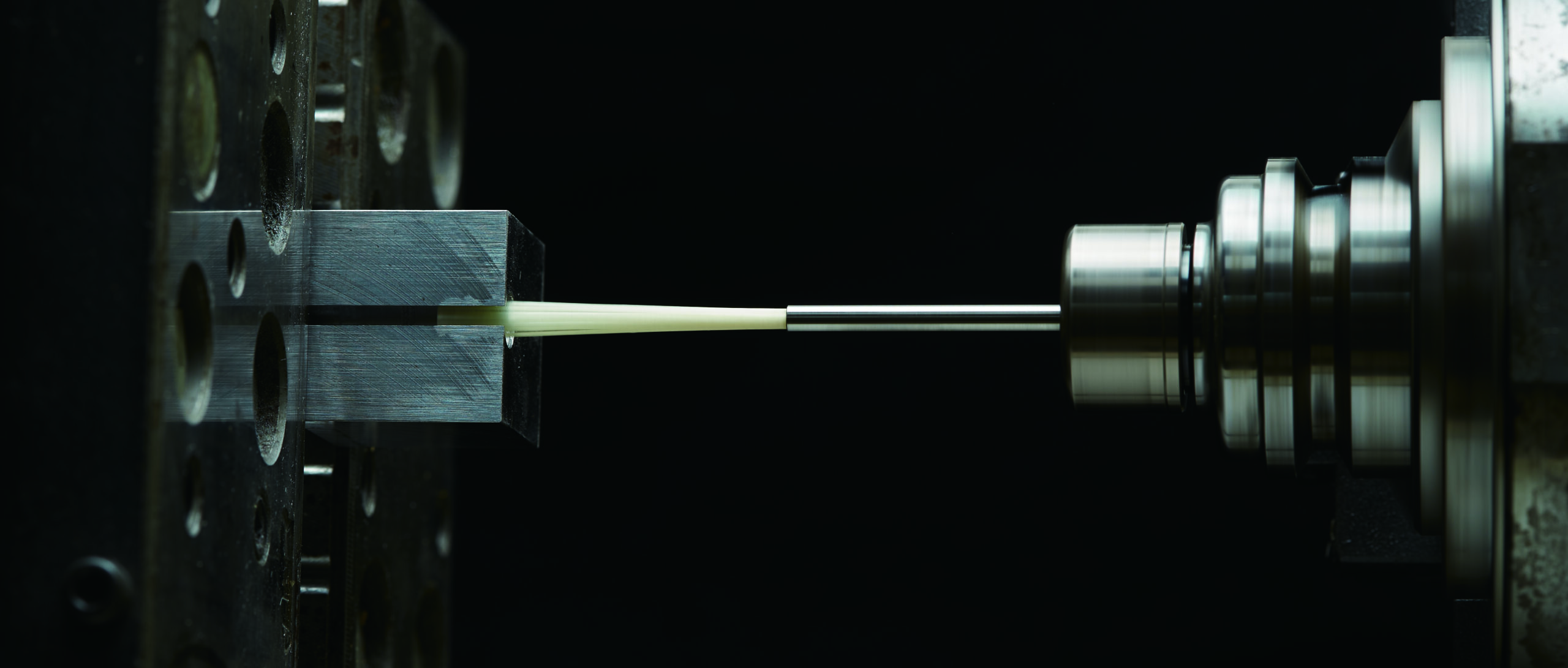

NOGA MT is excited to introduce the new UFIBER – Line of advanced ceramic fiber brushes designed to meet the highest standards of precision and durability in surface treatment applications.

Highlights:

- Nano-Technology Precision: UFIBER brushes utilize cutting-edge nano-technology to provide superior surface roughness control, exceptional wear resistance, and extended tool life. This innovation leads to fewer tool changes, longer operation times, and lower production costs.

- 3-in-1 Functionality: Combining deburring, polishing, and finishing in a single tool, UFIBER brushes streamline the manufacturing process, reducing the need for multiple tools and operations.

- Versatile Applications: Suitable for a wide range of tasks, including surface polishing, inner diameter polishing, and small point polishing, UFIBER brushes perform consistently even on complex geometries and hard-to-reach areas.

- Automation Ready: UFIBER brushes are compatible with CNC machines and robot arms, making them ideal for integration into automated manufacturing processes.

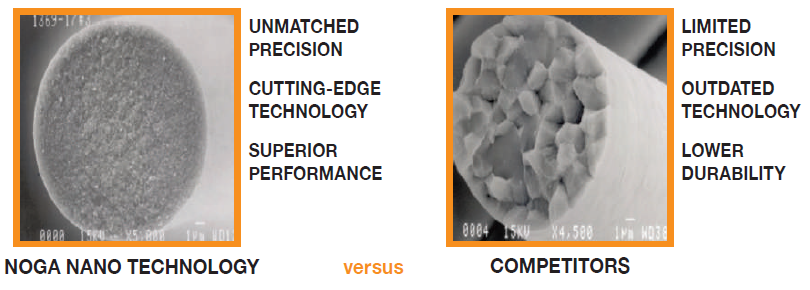

Nano Technology for Precision Polishing

UFIBER filament’s structure leverages nano-technology to refine the grain structure of each ceramic fiber, transitioning from traditional micron-sized grains to state-of-the-art nano-sized grains. This innovation allows each fiber to maintain its edge throughout the polishing process, ensuring a consistently smooth and precise finish while offering superior wear resistance and durability.

Benefits of using UFIBER

- 3-in-1 Functionality: UFIBER brushes combine deburring, polishing, and finishing in a single tool. This multifunctional capability reduces the need for multiple tools and operations, streamlining the manufacturing process and saving time and costs.

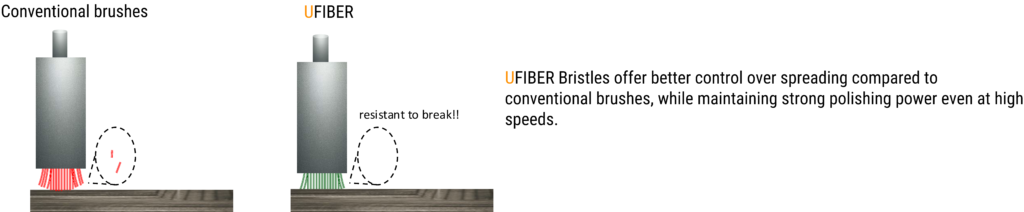

- Extended Tool Life: UFIBER ceramic fiber bristles offer better control over spreading compared to conventional brushes, while maintaining strong polishing power even at high speeds. This leads to a longer lifespan for the brushes, reducing the need for frequent replacements.

- Time Efficiency: UFIBER brushes have 60 times more grinding power, reducing the process time by 20% compared to abrasive nylon brushes. This efficiency translates into faster production cycles and lower overall costs.

- Stable Grinding Power: UFIBER brushes provide consistent grinding power, supporting the automation of deburring and tool mark removal without the need to frequently change the brush shape.

- Superior Surface Finish: The nano-bonded UFIBER bristles reduce polishing scratches, achieving a finer surface finish compared to conventional nylon brushes or ceramic bristles that use micro-bond technology.

- High Bending Strength: The brushes retain their shape and performance even under high RPM conditions, ensuring reliable operation and consistent results.

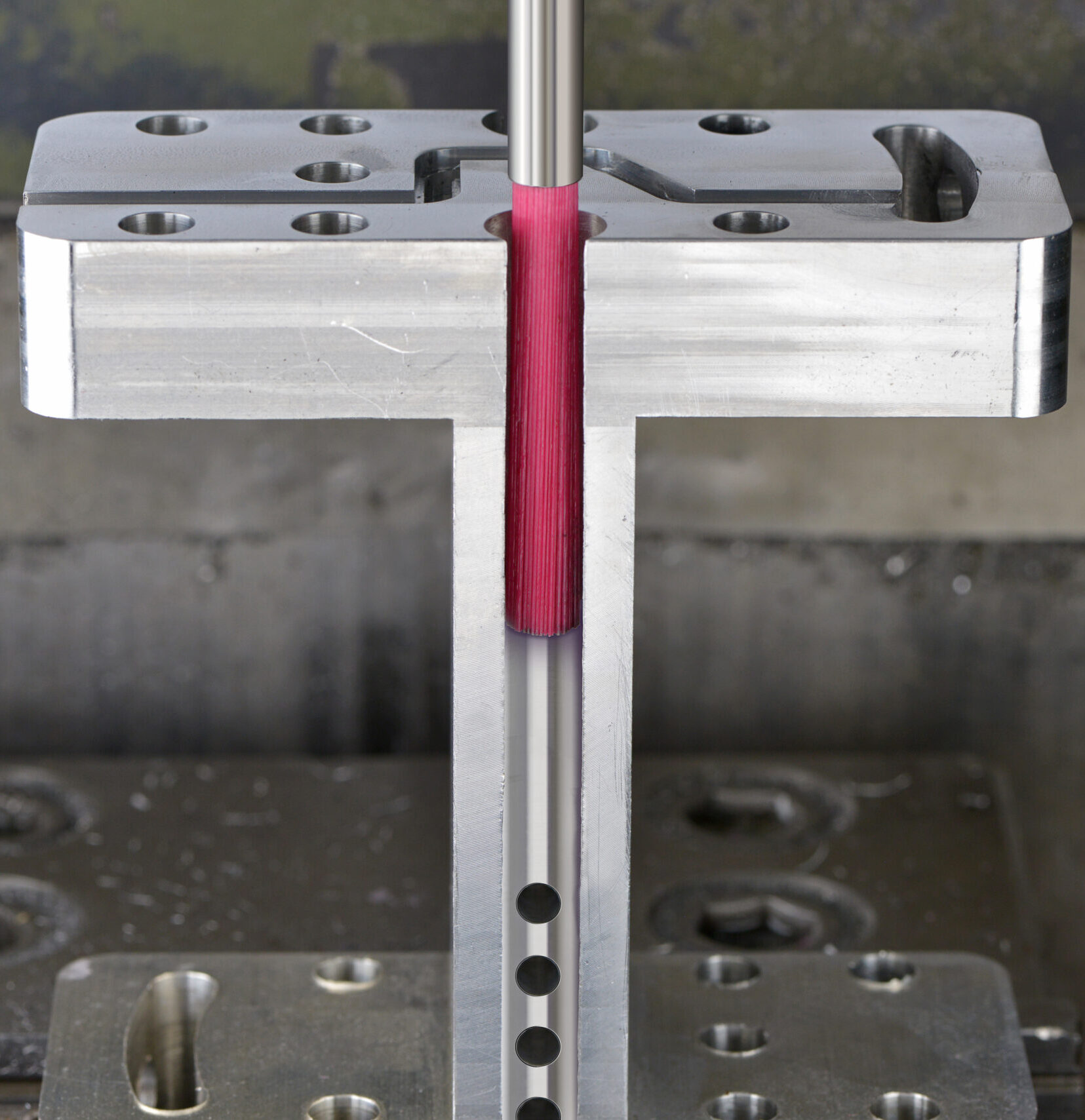

- Centrifugal Adaptability: Cross-hole brushes expand under centrifugal forces, perfectly fitting pilot hole diameters for enhanced versatility, making them ideal for various detailed and intricate tasks.

- Versatility: UFIBER brushes excel in a wide range of applications and materials, with 10 different bristle grits available, making them suitable for diverse industries and tasks.

Applications

- UFIBER bristles are available in grits ranging from #150 to #6000, providing flexibility to handle various work materials and burr conditions.

- The UFIBER brushes are suitable for any type of material in the market, including composite materials (FRP), copper, aluminium, SUS, carbon steels, stainless steel, and hardened materials. This versatility makes UFIBER brushes ideal for a wide range of industrial applications, ensuring high performance across various materials.

- Automotive Industry: Ideal for deburring and finishing engine components, transmission parts, and other metal surfaces, UFIBER brushes ensure smooth finishes and high precision, critical in automotive manufacturing.

- Aerospace: UFIBER brushes are suitable for precision surface treatment of aircraft components, ensuring compliance with stringent industry standards for safety and performance.

- Medical Devices: The brushes ensure smooth, polished finishes on surgical instruments and implants, which are critical for both functionality and safety in medical applications.

- General Manufacturing: UFIBER brushes are versatile enough to be used in various manufacturing processes, including metalworking, plastics, and composites. They can handle different materials and are adaptable to a wide range of surface treatment needs.

UFIBER bristles are available in grits ranging from #150 to #6000, providing flexibility to handle various work materials and burr conditions.

Selecting the right brush type that suits your application:

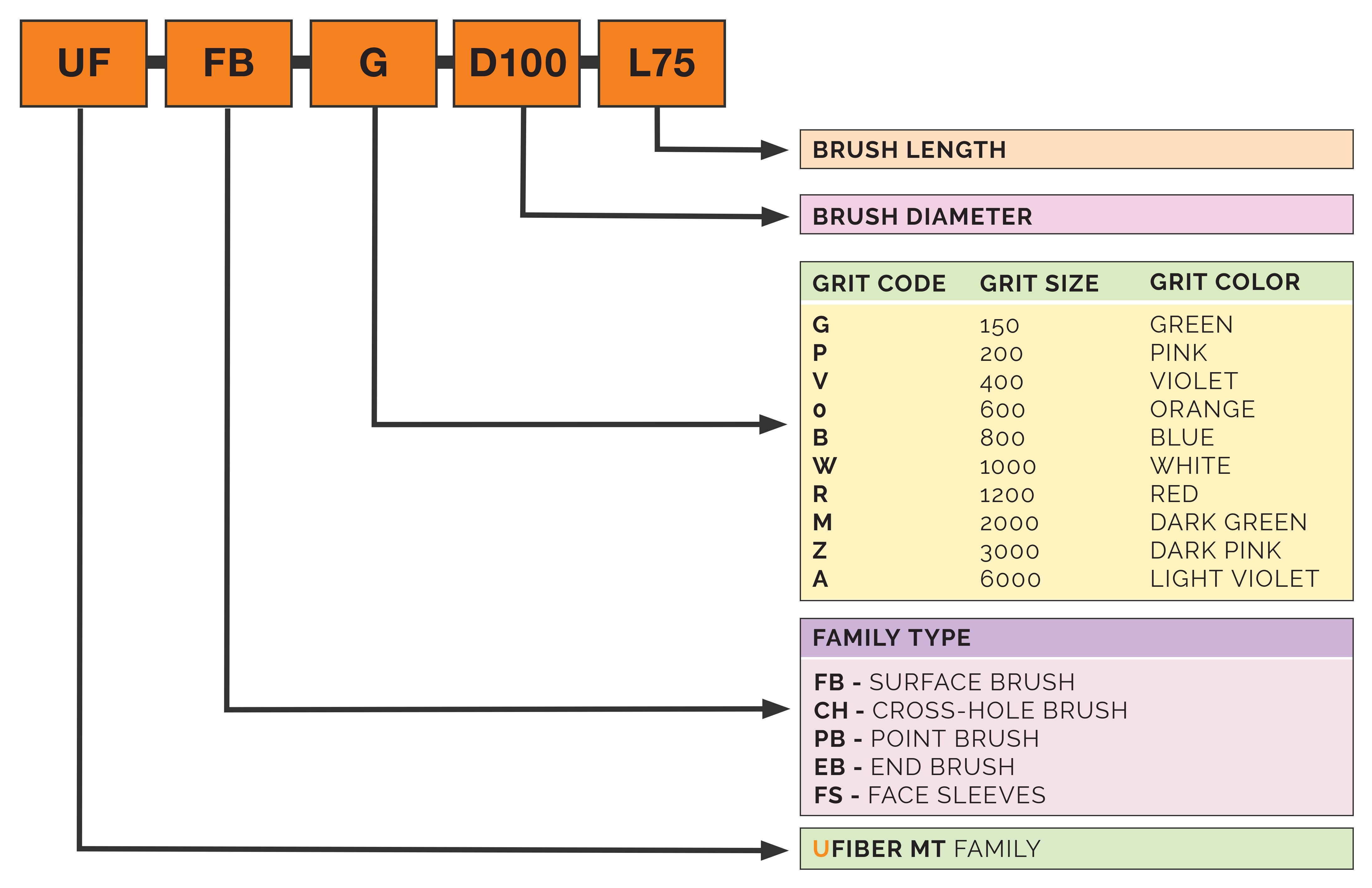

UFIBER brushes coding system specifications and identification:

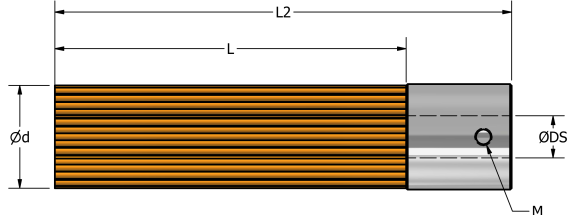

Surface-Brush item list:

|

SKU# |

DESCRIPTION |

Grit Size |

Ød |

L |

L2 |

ØDS |

Spare Parts (1) (For M) |

Weight |

Depth Of Cut (DOC) |

Recommended |

Max. Feed |

Max. Brush Projection(2) |

|||||

|

Clamping Screw |

SKU# |

LN Key |

SKU# |

Polishing |

Deburring |

Max. |

|||||||||||

|

UF1106 |

UF-FB-G-D006-L30 |

150 |

Ø6 |

30 |

42.5 |

N/A |

N/A |

N/A |

N/A |

N/A |

3 |

0.2 |

0.5 |

1.2 |

9000-12000 |

2000 |

10 |

|

UF1206 |

UF-FB-P-D006-L30 |

200 |

|||||||||||||||

|

UF1306 |

UF-FB-V-D006-L30 |

400 |

|||||||||||||||

|

UF1406 |

UF-FB-O-D006-L30 |

600 |

|||||||||||||||

|

UF1506 |

UF-FB-B-D006-L30 |

800 |

|||||||||||||||

|

UF1606 |

UF-FB-W-D006-L30 |

1000 |

|||||||||||||||

|

UF1706 |

UF-FB-R-D006-L30 |

1200 |

|||||||||||||||

|

UF1806 |

UF-FB-M-D006-L30 |

2000 |

|||||||||||||||

|

UF1906 |

UF-FB-Z-D006-L30 |

3000 |

|||||||||||||||

|

UF1006 |

UF-FB-A-D006-L30 |

6000 |

|||||||||||||||

|

UF1115 |

UF-FB-G-D015-L50 |

150 |

Ø15 |

50 |

65 |

Ø6 |

M3*0.5*4 |

UF0019 |

1.5 |

DH0005 |

7 |

0.2 |

0.5 |

1.2 |

5700-7200 |

2000 |

10 |

|

UF1215 |

UF-FB-P-D015-L50 |

200 |

|||||||||||||||

|

UF1315 |

UF-FB-V-D015-L50 |

400 |

|||||||||||||||

|

UF1415 |

UF-FB-O-D015-L50 |

600 |

|||||||||||||||

|

UF1515 |

UF-FB-B-D015-L50 |

800 |

|||||||||||||||

|

UF1615 |

UF-FB-W-D015-L50 |

1000 |

|||||||||||||||

|

UF1715 |

UF-FB-R-D015-L50 |

1200 |

|||||||||||||||

|

UF1815 |

UF-FB-M-D015-L50 |

2000 |

|||||||||||||||

|

UF1915 |

UF-FB-Z-D015-L50 |

3000 |

|||||||||||||||

|

UF1015 |

UF-FB-A-D015-L50 |

6000 |

|||||||||||||||

|

UF1125 |

UF-FB-G-D025-L75 |

150 |

Ø25 |

75 |

100 |

Ø9 |

M4*0.7*8 |

UF0018 |

2 |

UF0020 |

21 |

0.2 |

0.5 |

1.2 |

5000-6000 |

2000 |

10 |

|

UF1225 |

UF-FB-P-D025-L75 |

200 |

|||||||||||||||

|

UF1325 |

UF-FB-V-D025-L75 |

400 |

|||||||||||||||

|

UF1425 |

UF-FB-O-D025-L75 |

600 |

|||||||||||||||

|

UF1525 |

UF-FB-B-D025-L75 |

800 |

|||||||||||||||

|

UF1625 |

UF-FB-W-D025-L75 |

1000 |

|||||||||||||||

|

UF1725 |

UF-FB-R-D025-L75 |

1200 |

|||||||||||||||

|

UF1825 |

UF-FB-M-D025-L75 |

2000 |

|||||||||||||||

|

UF1925 |

UF-FB-Z-D025-L75 |

3000 |

|||||||||||||||

|

UF1025 |

UF-FB-A-D025-L75 |

6000 |

|||||||||||||||

|

UF1140 |

UF-FB-G-D040-L75 |

150 |

Ø40 |

75 |

96 |

Ø12 |

M6*1.0*8 |

PC0044 |

3 |

DB0007 |

26 |

0.2 |

0.5 |

1.2 |

2700-3600 |

2000 |

10 |

|

UF1240 |

UF-FB-P-D040-L75 |

200 |

|||||||||||||||

|

UF1340 |

UF-FB-V-D040-L75 |

400 |

|||||||||||||||

|

UF1440 |

UF-FB-O-D040-L75 |

600 |

|||||||||||||||

|

UF1540 |

UF-FB-B-D040-L75 |

800 |

|||||||||||||||

|

UF1640 |

UF-FB-W-D040-L75 |

1000 |

|||||||||||||||

|

UF1740 |

UF-FB-R-D040-L75 |

1200 |

|||||||||||||||

|

UF1840 |

UF-FB-M-D040-L75 |

2000 |

|||||||||||||||

|

UF1940 |

UF-FB-Z-D040-L75 |

3000 |

|||||||||||||||

|

UF1040 |

UF-FB-A-D040-L75 |

6000 |

|||||||||||||||

|

UF1160 |

UF-FB-G-D060-L75 |

150 |

Ø60 |

75 |

96 |

Ø13 |

M6*1.0*20 |

UF0016 |

3 |

DB0007 |

70 |

0.2 |

0.5 |

1.2 |

1800-2400 |

2000 |

10 |

|

UF1260 |

UF-FB-P-D060-L75 |

200 |

|||||||||||||||

|

UF1360 |

UF-FB-V-D060-L75 |

400 |

|||||||||||||||

|

UF1460 |

UF-FB-O-D060-L75 |

600 |

|||||||||||||||

|

UF1560 |

UF-FB-B-D060-L75 |

800 |

|||||||||||||||

|

UF1660 |

UF-FB-W-D060-L75 |

1000 |

|||||||||||||||

|

UF1760 |

UF-FB-R-D060-L75 |

1200 |

|||||||||||||||

|

UF1860 |

UF-FB-M-D060-L75 |

2000 |

|||||||||||||||

|

UF1960 |

UF-FB-Z-D060-L75 |

3000 |

|||||||||||||||

|

UF1060 |

UF-FB-A-D060-L75 |

6000 |

|||||||||||||||

|

UF1100 |

UF-FB-G-D100-L75 |

150 |

Ø100 |

75 |

97 |

Ø16 |

M6*1.0*25 |

UF0015 |

3 |

DB0007 |

140 |

0.2 |

0.5 |

1.2 |

1000-1400 |

2000 |

10 |

|

UF1200 |

UF-FB-P-D100-L75 |

200 |

|||||||||||||||

|

UF1300 |

UF-FB-V-D100-L75 |

400 |

|||||||||||||||

|

UF1400 |

UF-FB-O-D100-L75 |

600 |

|||||||||||||||

|

UF1500 |

UF-FB-B-D100-L75 |

800 |

|||||||||||||||

|

UF1600 |

UF-FB-W-D100-L75 |

1000 |

|||||||||||||||

|

UF1700 |

UF-FB-R-D100-L75 |

1200 |

|||||||||||||||

|

UF1800 |

UF-FB-M-D100-L75 |

2000 |

|||||||||||||||

|

UF1900 |

UF-FB-Z-D100-L75 |

3000 |

|||||||||||||||

|

UF1000 |

UF-FB-A-D100-L75 |

6000 |

|||||||||||||||

(1)The surface brush comes with 2 set-screws for mounting a shaft. For more details, see “Versatile Surface Brush for Efficient Cross-Hole Burr Removal” below.

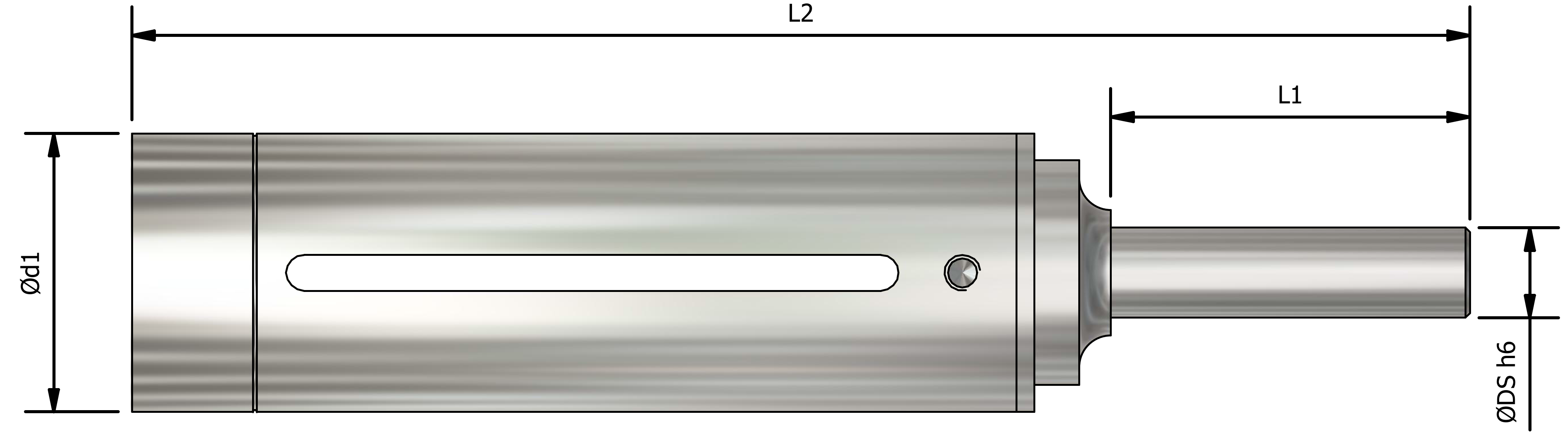

(2)When mounted with corresponded sleeve.

Surface brush sleeve item list:

|

Surface Brush |

SKU# |

Description |

Ød1 external mm /Inch |

ØDS mm /Inch |

L1 mm /Inch |

L2 mm /Inch |

Weight gram |

Sleeve Spare Parts |

|||

|

Clamping Screw M*P*Length (mm) |

SKU# |

LN Key S (mm) |

SKU# |

||||||||

|

Ø6 /0.236″ |

UF5506 |

UF-FS-6-C06-L70 |

10 /0.394” |

Ø6 /0.236″ |

30 /1.181″ |

71 /2.795″ |

30 |

M3*0.5*4 |

UF0010 |

2.5 |

UF0021 |

|

Ø15 /0.590″ |

UF5515 |

UF-FS-15-C06-L90 |

18.5 /0.728” |

Ø6 /0.236″ |

30 /1.181″ |

92 /3.622″ |

40 |

M3*0.5*6 |

UF0011 |

2 |

UF0020 |

|

Ø25 /0.984″ |

UF5525 |

UF-FS-25-C10-L140 |

30 1.181” |

Ø10 /0.394″ |

30 /1.181″ |

149 /5.866″ |

160 |

M4*0.7*10 |

UF0012 |

2.5 |

UF0021 |

|

Ø40 /1.575″ |

UF5540 |

UF-FS-40-C12-L140 |

45 /1.772” |

Ø12 /0.472″ |

30 /1.181″ |

135 5.315″ |

200 |

M6*1.0*10 |

UF0013 |

4 |

UF0022 |

|

Ø60 /2.362” |

UF5560 |

UF-FS-60-C12-L145 |

67 /2.638” |

Ø12 /0.472″ |

40 /1.575″ |

145 /5.708″ |

320 |

M6*1.0*10 |

UF0013 |

4 |

UF0022 |

|

Ø100 /3.937″ |

UF5500 |

UF-FS-100-C16-L155 |

110 /4.330” |

Ø16 /0.630″ |

40 /1.575″ |

155 /6.102″ |

670 |

M8*1.25*16 |

UF0014 |

5 |

UF0023 |

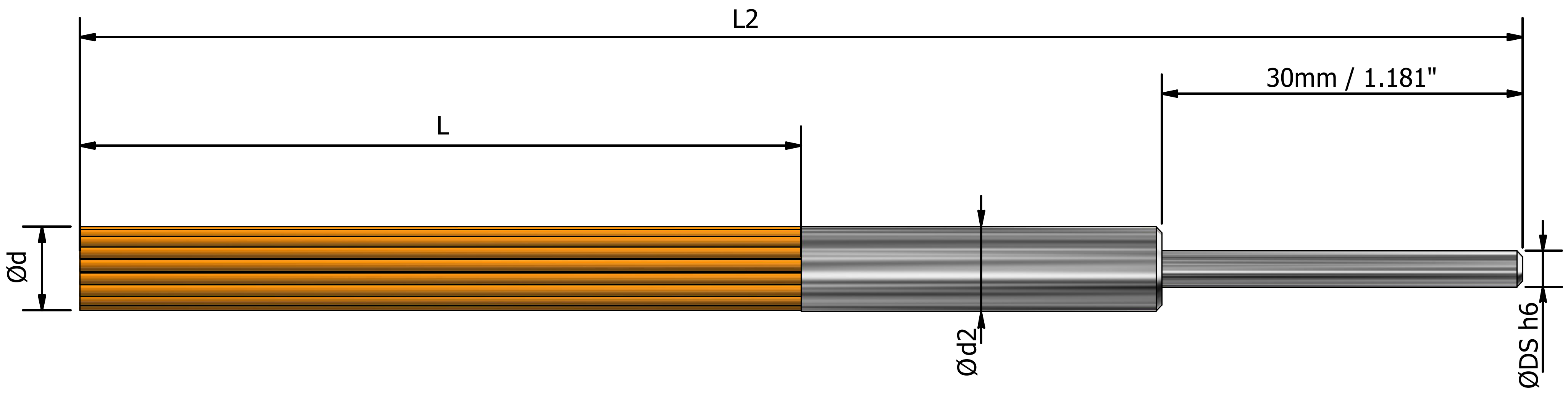

Cross-Hole item list:

SKU# | DESCRIPTION | Grit Size | Ød mm | L mm | Ød2 mm | L2 mm | ØDS mm | Weight gram | Maximum Spindle Speed Min-1 | Suitable Pilot-hole diameter | |

Grit #150-#1000 mm | Grit #1200-#6000 mm | ||||||||||

UF2115 | UF-CH-G-D015-L50 | 150 | Ø1.5 | 50 | Ø2.5 | 120 | Ø3 | 3 | 20000 | 3.5-5 | 3.5-5 |

UF2215 | UF-CH-P-D015-L50 | 200 | |||||||||

UF2315 | UF-CH-V-D015-L50 | 400 | |||||||||

UF2415 | UF-CH-O-D015-L50 | 600 | |||||||||

UF2515 | UF-CH-B-D015-L50 | 800 | |||||||||

UF2615 | UF-CH-W-D015-L50 | 1000 | |||||||||

UF2715 | UF-CH-R-D015-L50 | 1200 | |||||||||

UF2815 | UF-CH-M-D015-L50 | 2000 | |||||||||

UF2915 | UF-CH-Z-D015-L50 | 3000 | |||||||||

UF2015 | UF-CH-A-D015-L50 | 6000 | |||||||||

UF2130 | UF-CH-G-D030-L60 | 150 | Ø3 | 60 | Ø4 | 130 | Ø3 | 6 | 14000 | 5-7 | – |

UF2230 | UF-CH-P-D030-L60 | 200 | |||||||||

UF2330 | UF-CH-V-D030-L60 | 400 | |||||||||

UF2430 | UF-CH-O-D030-L60 | 600 | |||||||||

UF2530 | UF-CH-B-D030-L60 | 800 | |||||||||

UF2630 | UF-CH-W-D030-L60 | 1000 | |||||||||

UF2730 | UF-CH-R-D030-L50 | 1200 | 50 | 120 | 14000 | – | 5-7 | ||||

UF2830 | UF-CH-M-D030-L50 | 2000 | |||||||||

UF2930 | UF-CH-Z-D030-L50 | 3000 | |||||||||

UF2030 | UF-CH-A-D030-L50 | 6000 | |||||||||

UF2150 | UF-CH-G-D050-L60 | 150 | Ø5 | 60 | Ø6 | 130 | Ø6 | 17 | 14000 | 7-9 | – |

UF2250 | UF-CH-P-D050-L60 | 200 | |||||||||

UF2350 | UF-CH-V-D050-L60 | 400 | |||||||||

UF2450 | UF-CH-O-D050-L60 | 600 | |||||||||

UF2550 | UF-CH-B-D050-L60 | 800 | |||||||||

UF2650 | UF-CH-W-D050-L60 | 1000 | |||||||||

UF2750 | UF-CH-R-D050-L50 | 1200 | 50 | 120 | 14000 | – | 8-10 | ||||

UF2850 | UF-CH-M-D050-L50 | 2000 | |||||||||

UF2950 | UF-CH-Z-D050-L50 | 3000 | |||||||||

UF2050 | UF-CH-A-D050-L50 | 6000 | |||||||||

UF2170 | UF-CH-G-D070-L60 | 150 | Ø7 | 60 | Ø8 | 130 | Ø6 | 24 | 14000 | 9-14 | – |

UF2270 | UF-CH-P-D070-L60 | 200 | |||||||||

UF2370 | UF-CH-V-D070-L60 | 400 | |||||||||

UF2470 | UF-CH-O-D070-L60 | 600 | |||||||||

UF2570 | UF-CH-B-D070-L60 | 800 | |||||||||

UF2670 | UF-CH-W-D070-L60 | 1000 | |||||||||

UF2770 | UF-CH-R-D070-L50 | 1200 | 50 | 120 | 14000 | – | 10-20 | ||||

UF2870 | UF-CH-M-D070-L50 | 2000 | |||||||||

UF2970 | UF-CH-Z-D070-L50 | 3000 | |||||||||

UF2070 | UF-CH-A-D070-L50 | 6000 | |||||||||

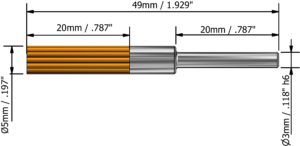

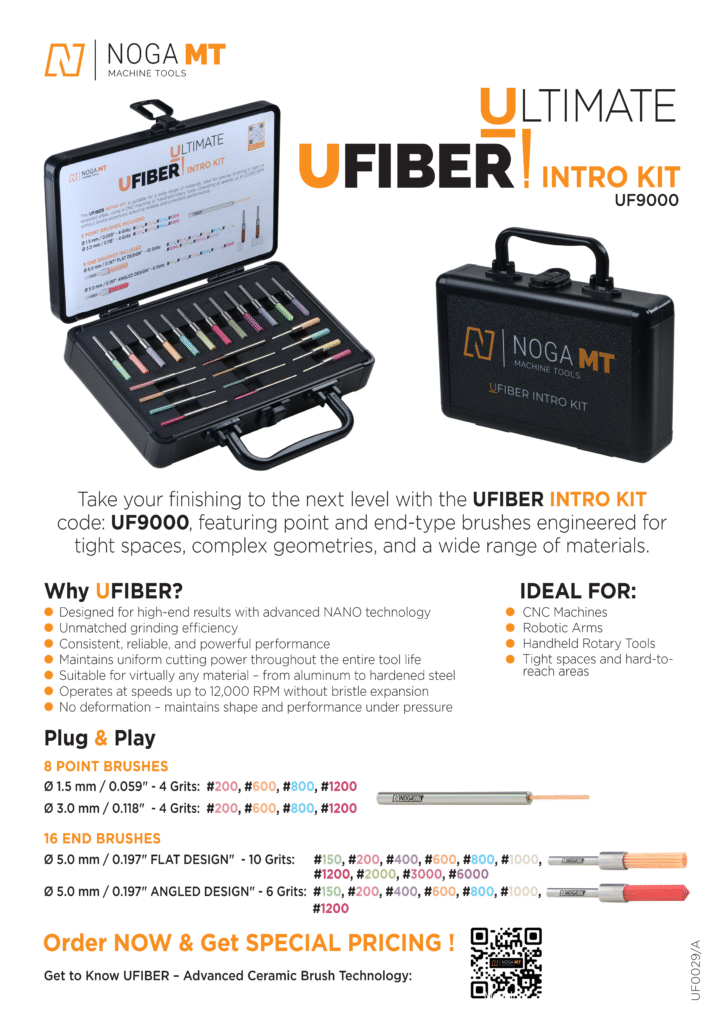

End-Brush item list:

SKU# | DESCRIPTION | Grit Size | Weight gram | Maximum Spindle Speed Min-1 |

UF4150 | UF-EB-G-D5-L20 | 150 | 3 | 12000 |

UF4250 | UF-EB-P-D5-L20 | 200 | ||

UF4350 | UF-EB-V-D5-L20 | 400 | ||

UF4450 | UF-EB-O-D5-L20 | 600 | ||

UF4550 | UF-EB-B-D5-L20 | 800 | ||

UF4650 | UF-EB-W-D5-L20 | 1000 | ||

UF4750 | UF-EB-R-D5-L20 | 1200 | ||

UF4850 | UF-EB-M-D5-L20 | 2000 | ||

UF4950 | UF-EB-Z-D5-L20 | 3000 | ||

UF4050 | UF-EB-A-D5-L20 | 6000 |

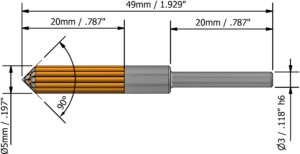

SKU# | DESCRIPTION | Grit Size | Weight gram | Maximum Spindle Speed Min-1 |

UF6150 | UF-EB45-G-D5-L20 | 150 | 3 | 12000 |

UF6250 | UF-EB45-P-D5-L20 | 200 | ||

UF6350 | UF-EB45-V-D5-L20 | 400 | ||

UF6450 | UF-EB45-O-D5-L20 | 600 | ||

UF6550 | UF-EB45-B-D5-L20 | 800 | ||

UF6650 | UF-EB45-W-D5-L20 | 1000 | ||

UF6750 | UF-EB45-R-D5-L20 | 1200 | ||

UF6850 | UF-EB45-M-D5-L20 | 2000 | ||

UF6950 | UF-EB45-Z-D5-L20 | 3000 | ||

UF6050 | UF-EB45-A-D5-L20 | 6000 |

Point-Brush item list:

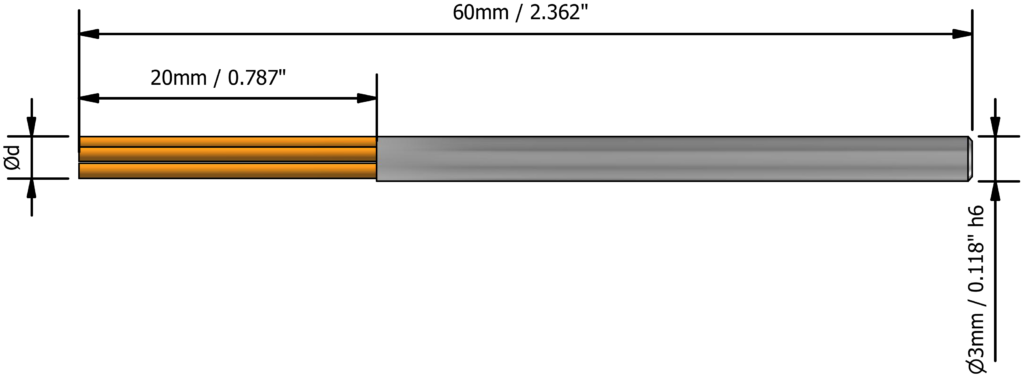

Dimensions for 1.0-2.0mm (0.039-0.079") Point-brush

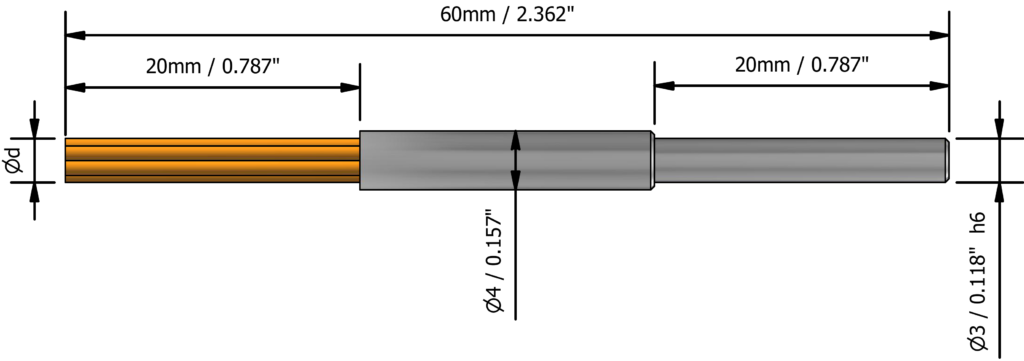

Dimensions only for 2.5-3mm (0.098-0.118") Point-brush

|

DESCRIPTION |

Grit Size |

Ød mm |

Weight gram |

Maximum Spindle Speed Min-1 |

|

|

UF3110 |

UF-PB-G-D1-L20 |

150 |

Ø1.0 /0.039” |

2 |

12000 |

|

UF3210 |

UF-PB-P-D1-L20 |

200 |

|||

|

UF3310 |

UF-PB-V-D1-L20 |

400 |

|||

|

UF3410 |

UF-PB-O-D1-L20 |

600 |

|||

|

UF3510 |

UF-PB-B-D1-L20 |

800 |

|||

|

UF3610 |

UF-PB-W-D1-L20 |

1000 |

|||

|

UF3710 |

UF-PB-R-D1-L20 |

1200 |

|||

|

UF3810 |

UF-PB-M-D1-L20 |

2000 |

|||

|

UF3910 |

UF-PB-Z-D1-L20 |

3000 |

|||

|

UF3010 |

UF-PB-A-D1-L20 |

6000 |

|||

|

UF3115 |

UF-PB-G-D1.5-L20 |

150 |

Ø1.5 /0.059” |

2 |

12000 |

|

UF3215 |

UF-PB-P-D1.5-L20 |

200 |

|||

|

UF3315 |

UF-PB-V-D1.5-L20 |

400 |

|||

|

UF3415 |

UF-PB-O-D1.5-L20 |

600 |

|||

|

UF3515 |

UF-PB-B-D1.5-L20 |

800 |

|||

|

UF3615 |

UF-PB-W-D1.5-L20 |

1000 |

|||

|

UF3715 |

UF-PB-R-D1.5-L20 |

1200 |

|||

|

UF3815 |

UF-PB-M-D1.5-L20 |

2000 |

|||

|

UF3915 |

UF-PB-Z-D1.5-L20 |

3000 |

|||

|

UF3015 |

UF-PB-A-D1.5-L20 |

6000 |

|||

|

UF3120 |

UF-PB-G-D2-L20 |

150 |

Ø2.0 /0.079” |

2 |

12000 |

|

UF3220 |

UF-PB-P-D2-L20 |

200 |

|||

|

UF3320 |

UF-PB-V-D2-L20 |

400 |

|||

|

UF3420 |

UF-PB-O-D2–L20 |

600 |

|||

|

UF3520 |

UF-PB-B-D2–L20 |

800 |

|||

|

UF3620 |

UF-PB-W-D2-L20 |

1000 |

|||

|

UF3720 |

UF-PB-R-D2-L20 |

1200 |

|||

|

UF3820 |

UF-PB-M-2-L20 |

2000 |

|||

|

UF3920 |

UF-PB-Z-D2-L20 |

3000 |

|||

|

UF3020 |

UF-PB-A-D2-L20 |

6000 |

|

SKU# |

DESCRIPTION |

Grit Size |

Ød mm |

Weight gram |

Maximum Spindle Speed Min-1 |

|

UF3125 |

UF-PB-G-D2.5-L20 |

150 |

Ø2.5 /0.098” |

3 |

12000 |

|

UF3225 |

UF-PB-P-D2.5-L20 |

200 |

|||

|

UF3325 |

UF-PB-V-D2.5-L20 |

400 |

|||

|

UF3425 |

UF-PB-O-D2.5-L20 |

600 |

|||

|

UF3525 |

UF-PB-B-D2.5-L20 |

800 |

|||

|

UF3625 |

UF-PB-W-D2.5-L20 |

1000 |

|||

|

UF3725 |

UF-PB-R-D2.5-L20 |

1200 |

|||

|

UF3825 |

UF-PB-M-D2.5-L20 |

2000 |

|||

|

UF3925 |

UF-PB-Z-D2.5-L20 |

3000 |

|||

|

UF3025 |

UF-PB-A-D2.5-L20 |

6000 |

|||

|

UF3130 |

UF-PB-G-D3-L20 |

150 |

Ø3 /0.118” |

3 |

12000 |

|

UF3230 |

UF-PB-P-D03-L20 |

200 |

|||

|

UF3330 |

UF-PB-V-D3-L20 |

400 |

|||

|

UF3430 |

UF-PB-O-D3-L20 |

600 |

|||

|

UF3530 |

UF-PB-B-D3-L20 |

800 |

|||

|

UF3630 |

UF-PB-W-D3-L20 |

1000 |

|||

|

UF3730 |

UF-PB-R-D3-L20 |

1200 |

|||

|

UF3830 |

UF-PB-M-D3-L20 |

2000 |

|||

|

UF3930 |

UF-PB-Z-D3-L20 |

3000 |

|||

|

UF3030 |

UF-PB-A-D3-L20 |

6000 |

Questions & Answers UFIBER

UFIBER Advanced Fiber Brushes are innovative polishing tools designed using nano-technology for superior performance. They are ideal for surface finishing, deburring, and polishing applications on a variety of materials, including metals, composites, and hardened surfaces.

UFIBER offers a range of brush types tailored for different applications:

- Surface Type Brushes: For flat surface polishing.

- Cross-Hole Type Brushes: Ideal for deburring and polishing inner diameters of cross-holes.

- Point Type Brushes: Suitable for small point polishing tasks.

- End Type Brushes: Designed for precise end-face polishing.

UFIBER brushes are compatible with a wide range of materials, including:

- Composite materials (FRP)

- Copper and aluminum

- Stainless steel, carbon steels, and hardened materials

UFIBER brushes offer superior wear resistance, consistent surface roughness control, and longer lifespan compared to traditional abrasive brushes. Their nano-technology design ensures efficient and precise material removal.

Yes, UFIBER brushes are compatible with CNC machines and robot arms, making them ideal for automated manufacturing environments. They provide reliable and consistent performance in automated deburring and polishing tasks.

- Can UFIBER brushes be used with coolant?

Yes, UFIBER brushes can be used with or without coolant. Using coolant can enhance tool life and improve the surface finish.

Choosing the right UFIBER brush depends on the material, the shape of the workpiece, and the desired surface finish. Consult our product selection guide or contact our technical support team for personalized recommendations.

UFIBER brushes are easy to install. Ensure the correct brush size and type are selected, then mount the brush securely on your machine following the manufacturer’s guidelines. Always check that the brush is properly centered before operation.

Always wear appropriate personal protective equipment, such as safety glasses and gloves, when operating UFIBER brushes. Ensure that the machine guard is in place, and operate the brush within the recommended speed limits.

Store UFIBER brushes in a dry, cool environment away from direct sunlight. Inspect brushes regularly for wear or damage, and replace them as needed to maintain optimal performance.

Store UFIBER brushes in a dry, cool environment away from direct sunlight. Inspect brushes regularly for wear or damage, and replace them as needed to maintain optimal performance.

If you notice a decline in performance, check the brush for wear or damage. Ensure it is operating within the correct speed range and that the workpiece material is suitable. Replacing the brush may be necessary to restore performance.

- Why is the brush not achieving the expected surface finish?

Several factors can affect surface finish, including incorrect brush selection, inappropriate rotational speed, or excessive feed rates. Adjust these parameters as needed, or consult our technical support team for further guidance.

To prevent uneven wear, ensure the brush is properly centered during installation and operates within the recommended speed and feed settings. Regularly rotate the workpiece to distribute wear evenly across the brush.

- Are UFIBER brushes reusable?

UFIBER brushes can be used multiple times until they reach their wear limit. Regular inspection is advised to ensure the brush remains effective. Always replace worn brushes to maintain quality and efficiency.

UFIBER brushes are versatile and can be used with various machines, including CNC machining centers, lathes, drill presses, and robotic arms. Compatibility may vary based on brush type and application.

Yes, UFIBER offers customization options for brushes to meet specific application needs. Contact our sales team to discuss your requirements and explore available customization solutions.

- Where can I purchase UFIBER brushes?

UFIBER brushes are available through authorized distributors and our official website. For more information, please visit our contact page to find a distributor near you.

For technical support, please contact our support team via email or phone. We are here to help with product selection, troubleshooting, and any other inquiries.