Case Study #1 UBACK

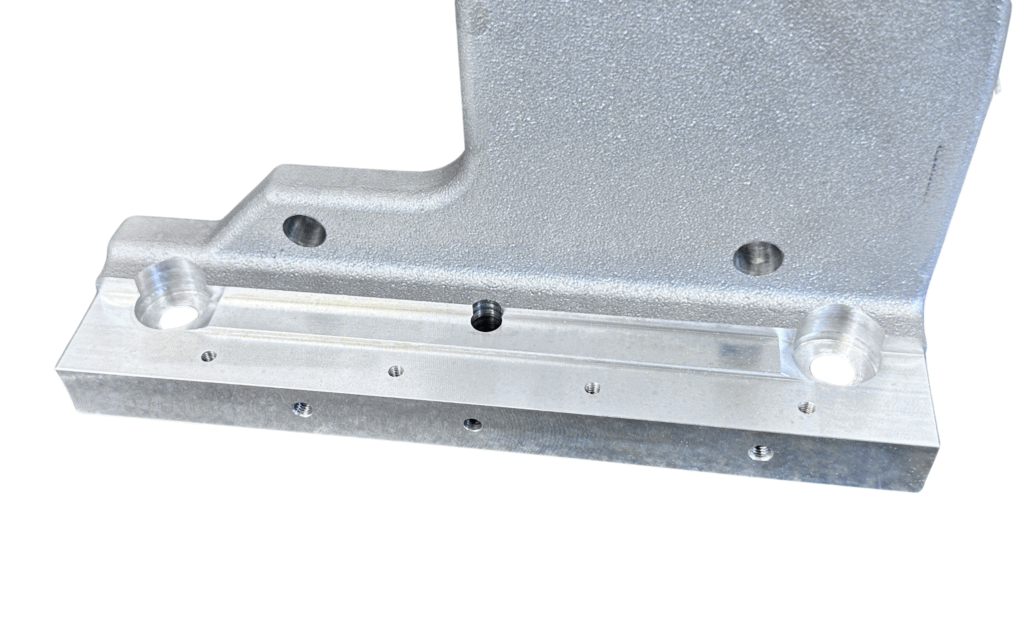

Industry: Automotive-structural supports

Goal: The customer was facing limitations in traditional counterboring and spot-facing tools:

- Inconsistent surface finish in Al-Si casting material.

- Tool wear leading to frequent replacements.

- Inefficient cycle times, reducing overall productivity.

Application details:

- Material: Aluminum casting, Alu Ac65. 12% Si

- Machine: Mazak Variaxis I600

- Adaptation SK40 (DIN69871)

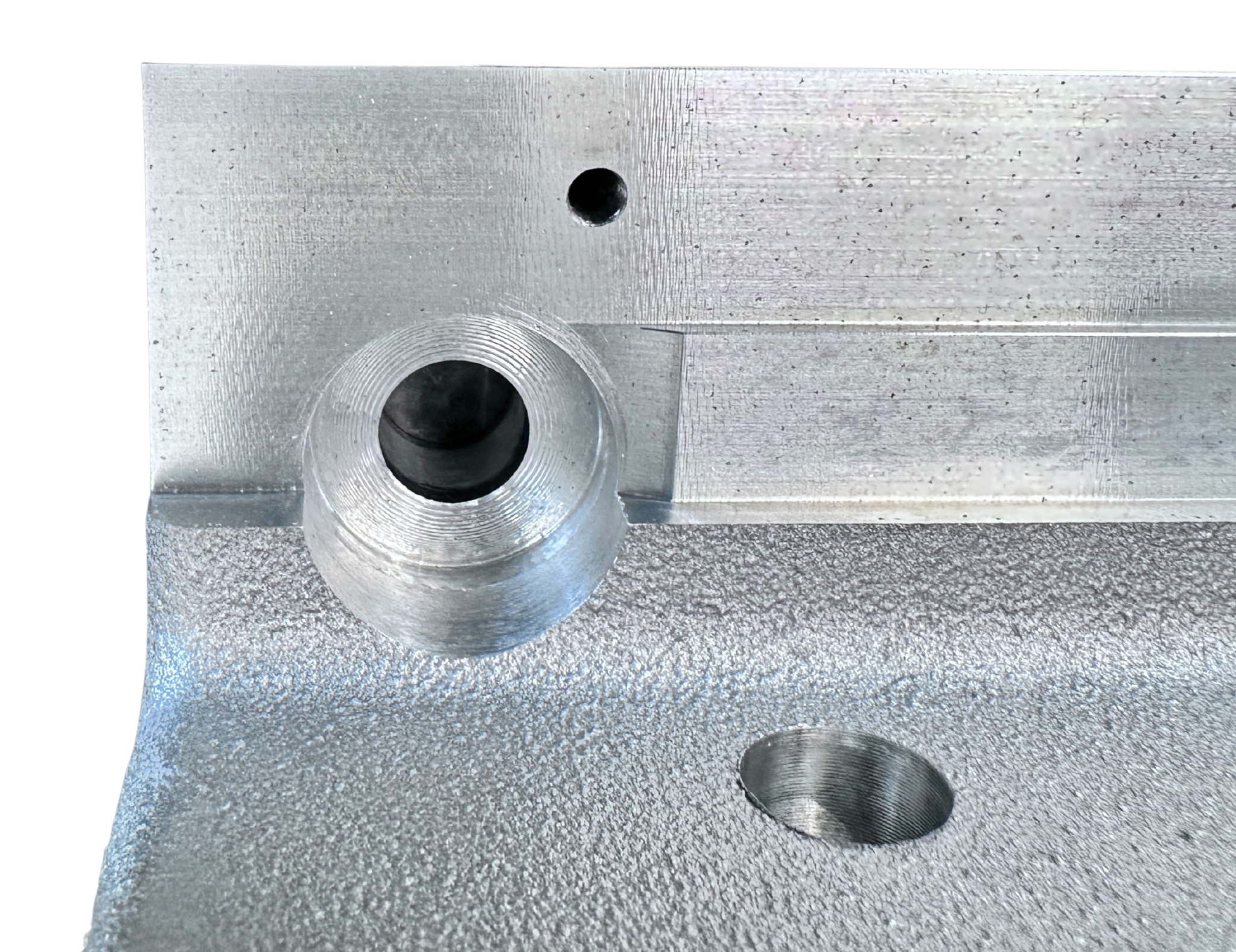

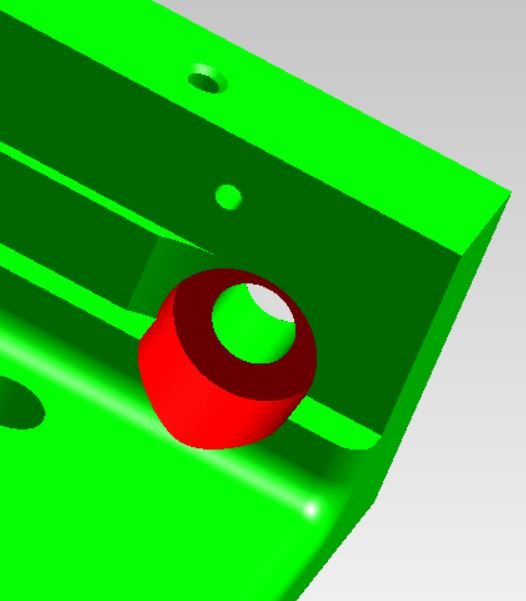

- Pilot Hole: Ø13mm / .512”

- Spotface: Ø25mm / .984” and interrupted cut

Tool-holder: UX3130, UX-d130-C-C16-H80-L133

Insert: US3007, US-d130-D250-C-R04-PL-NCT

Machining Parameters:

Ød Pilot | ØD Counterbore | S Spindle | F Table | vc Cutting | fz Feed | Coolant | |||||

mm | Inch | mm | Inch | RPM | mm/min | inch/min. | m/min. | sfm | mm | inch | |

13 | 0.512 | 25 | 0.984 | 2000 | 80 | 3.15 | 160 | 525 | 0.04 | 0.002 | Emulsion |